Additional Hot Spot Repair Service: Refractory Hot Spot Endoscopy!

The Insulcon Group has a new service additional to the refractory Hot Spot Repair Service: the HOT SPOT ENDOSCOPY.

The perfect service to accurately determine the internal damage at the furnace refractory linings!

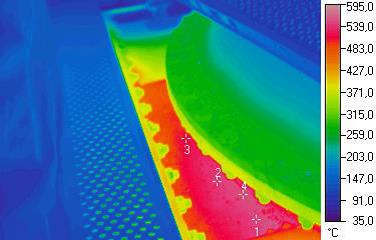

While the furnace is in full operation (in this case it is more than 1100°C inside!), one or more 50 mm holes are cut in the furnace wall nearby the Hot Spot area. Through the holes a water-cooled Endoscopy Lance Camera enters the furnace interior to provide a good look at the damaged refractory lining. This way our experts can determine the right procedures to fix the Hot Spot Repair in the best possible way.

In this video you can see that three Z-Blok (fiber) modules have dropped out of the lining, resulting in a 300 mm deep gap of 400 x 900 mm! Also, the shrinkage joints between the roof and wall lining are visible, which is the result of the by passing of hot flue gasses in between the casing and module lining, resulting in new Hot Spots

When the Hot Spot is eliminated by our Injection Mould, which fills up the total cavity, the progress will be again monitored through the Hot Spot Endoscopy Camera, as an additional control. And after the Hot Spot has changed into a Cold Spot the holes that were cut into the furnace wall will be covered (and closed) by small steel plates to prevent ingress of rain.

For more information about our Hot Spot Endoscopy service, please do not hesitate to e-mail us at hotspotrepair@insulcon.com. Or look at our websites www.insulcon.com / www.hot-spot-repair.com for more information or contact marketing@insulcon.com.